Project Management

Whether you are a local or international client, whether you require traditional construction services or untraditional ones, and whether your project is at its inception or tail end, our premium project management services have you covered.

Our competence lies in our in-depth knowledge and our abidance with the Project Management Institute (PMI) global standards. As such, we handle the planning, analysis, and proactive decision-making associated with every stage of the project lifecycle.

In this challenging yet deeply gratifying process, our PMI-certified project management professionals roll up their sleeves and lead cross-functional project teams who regularly facilitate the following aspects:

Program charters, work breakdown structures, staffing analysis, identification of project activities, governance procedures, standard reports, coding structures, metrics, and templates, detailed project schedules, validation and compression of schedules, time-cost tradeoff, generation of status memos, implementation of site facilities, risk mitigation, tight control of scopes, schedules, and budgets, and management of the design, planning, and execution stages.

see projects related

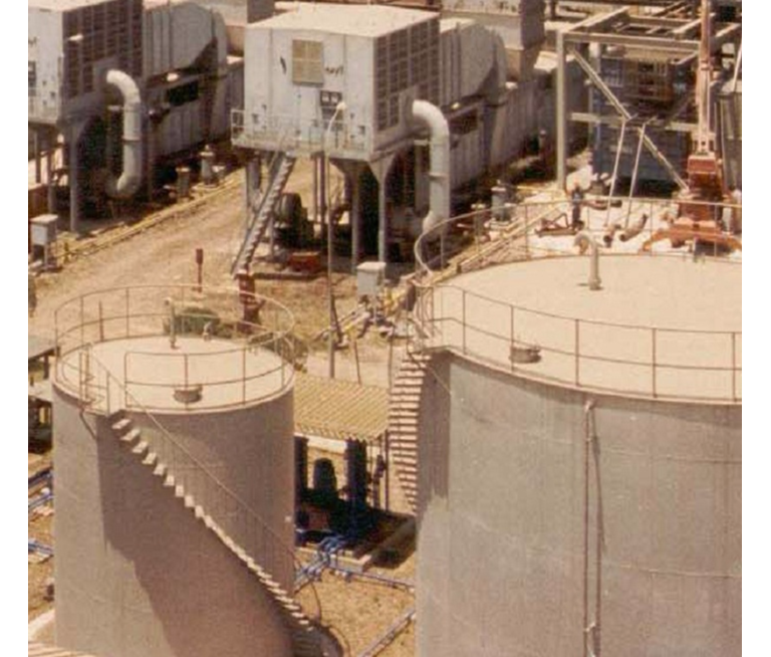

Damanhour Combined Cycle Power Station

Owned by the Egyptian Electricity Authority (EEA), the objective of the project was to upgrade the existing power station at Damanhour through the utilization of waste heat discharged to the atmosphere by gas turbines. The exhaust gases from the gas turbines were to be diverted through non-fired heat recovery boilers (HRSG) for the generation of steam. The generated steam produced an additional electrical power of 1×50 MW.

The project involved the addition of four heat recovery boilers to integrate four existing GE frame 5 Gas Turbines, into combined cycle mode of operation. This enabled the powering of 1×50 MW Turbo-Alternators.

The heat recovery boilers were to be arranged to produce superheated steam by extracting heat from the exhaust gases of the gas turbines. This superheated steam was to be used to drive a steam turbine generator. The heat recovery boilers were fitted to the gas turbines on a one- for-one basis. The superheated steam produced by four boilers was delivered to one main steam manifold which was connected to steam turbine generator of 50 MW steam driven nominal capacity.

The total plant consisting of heat recovery boilers, steam turbine generators and auxiliaries; was controlled and operated by a central control room. The plant also included: additional tank farms; cooling water systems fed by irrigation canals connected to the River Nile; electrical control and instrumentation systems; and civil/ structural works.

The project was implemented in four packages, namely:

- Heat Recovery Boiler Package, including: boilers and related structural steel, foundation works and associated facilities; pipe works; electrical cables and panels; instrumentation and control equipment; and some gas turbine modifications.

- Steam Turbine Package, including: steam turbines; alternators with necessary accessories; condensing plant and auxiliaries; main cooling water system; water treatment plant; fire protection system; compressed air system; cranes, hoists and handling equipment; electrical equipment; control and instrumentation equipment; and laboratory equipment.

- Electrical Power Package, including: circuit breakers; transformers; power boards; battery and charger systems; and associated cabling.

- Civil Works Package, including: turbine/control/ administration building, water treatment building and maintenance building (total area was 1,000 m2) piled foundations for heat recovery boilers construction; cooling water system (intake structure, pumping station, inlet and outlet culverts, and outfall structure); external works e.g. roads, cable ducts, fencing and gates.